In this article, You will read Fertilizer Industry in India – for UPSC IAS (Industry – Geography of India).

Fertilizer Industry

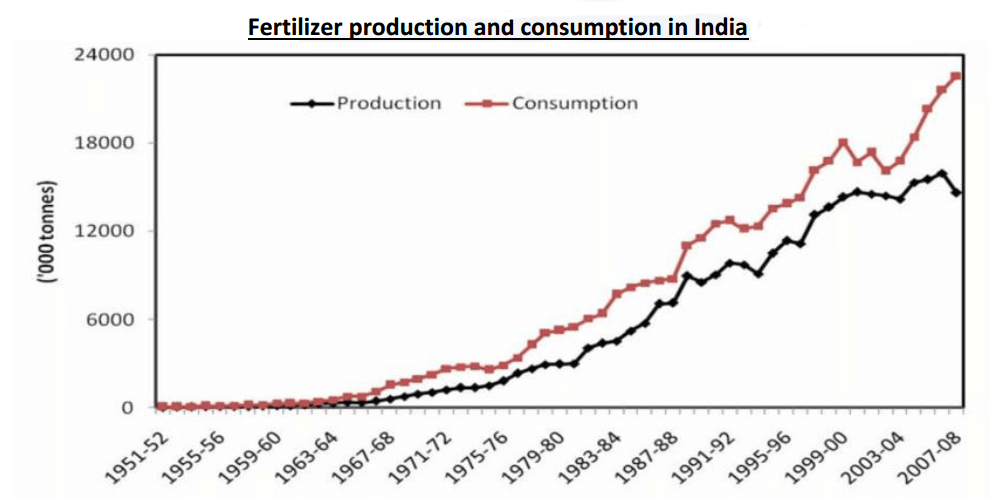

- The Indian fertilizer industry has made good progress in the case of Nitrogen-based fertilizers. India is the 2nd largest consumer of Urea fertilizers after China. India also ranks 2nd in the production of nitrogenous fertilizers and 3rd in phosphatic fertilizers. Potash requirement is met through imports since we have limited reserves of potash. Productions are largely state-controlled. Popular PSUs are The Fertilizer Corporation of India Ltd, National fertilizers Limited, Hindustan Fertilizer Corporation Ltd., etc.

- Fertilizer provided the cradle in which the HYV seeds and assured irrigation flourished in the form of the green revolution, mitigating the ever-multiplying problem of food security in India.

- Its importance can be gauged from the fact that the regions with high use of fertilizers are now known as ‘granaries of India.’ The fertilizers industry is the second most important industry in India after iron and steel.

- Decreasing fertility of the land and increasing population have raised the importance of this industry manifold. The fertilizer industry provides vital forward-backward linkages with other industries. Forward linkages are with agriculture and backward linkages are with petrochemical industries. The by-products of the petrochemical industry are used as raw materials in the fertilizers industry.

- General productivity of the fertilizers industry is low. India is still not self-reliant in fertilizer production (about 50% of fertilizers are imported).

- Further, there is a high Spatio-temporal variation in consumption. Fertilizer can most effectively be used with ample water. So rainfed areas (deprived of irrigation) constitute 70 % of agricultural land and still, they use only 20% of national Fertilizers consumption. On other hand Rabi crops are dominantly produced in Irrigated areas, so they consume about 66% of fertilizers while their share of total agriculture output is 33%

- India meets 85 percent its urea requirement through indigenous production but depends heavily on imports for its phosphate and potash (P & K) fertilizer requirements.

Growth and development

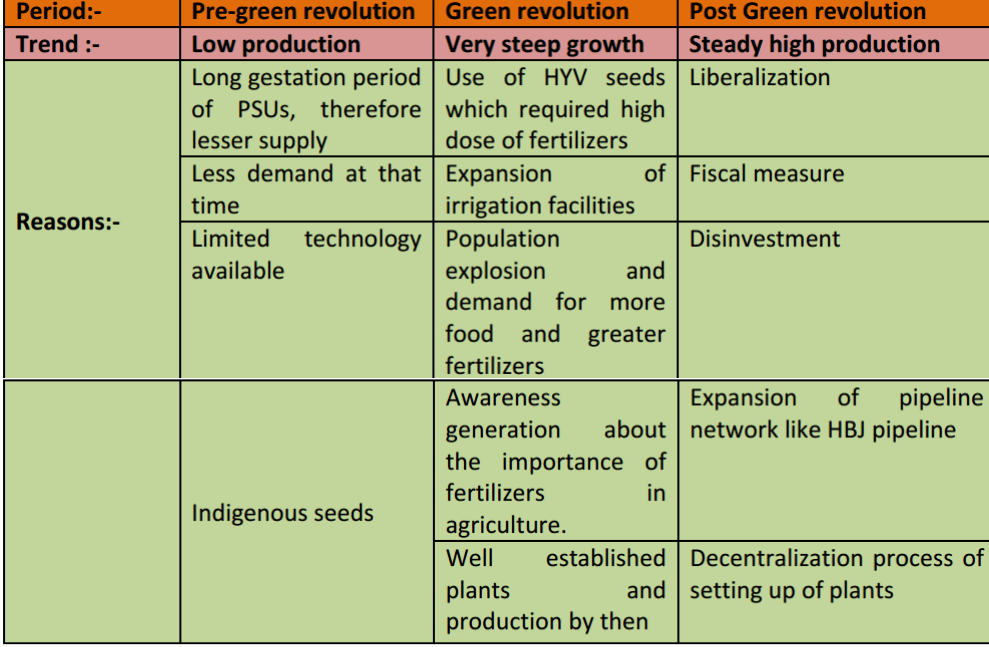

- It is one of the fastest-growing basic industries, which has taken rapid strides in recent years. Although the first superphosphate factory in the country was set up at Banipet (T.N) as early as 1906, India’s fertilizer industry is essentially post-independence development.

- The setting up of the Sindri plant in Bihar by Fertilizer Corporation of India Ltd. (FCI) in 1951 was a turning point and since then this industry has progressed steadily. The progress was, however, slow till 1966.

- Thereafter due to a series of factors, chief among which were HYV programmes, a faster expansion of irrigated area and introduction of urea as a straight fertilizer and the demand, led to the production of fertilizers grew sharply.

- Three decades of planning and development of the fertilizer industry has brought India to the frontline of a fertilizer-producing country.

- As far as Potassic (K) fertilizers is concerned, there is no indigenous capacity. The requirements are met entirely through imports. India meets its 80 % requirement of Urea (N), while it is heavily dependent on Imports for its potassium (K) and phosphorus (P) fertilizer requirements.

- The fertilizer industry of India is developed both under the Public and Private sectors.

- During 1951-52, the production capacity of nitrogen fertilizer in India was a mere 85,000 tonnes, which finally shot up to 11.07 million tonnes in 1999-2000. In this period, the increase of Phosphate fertilizer production capacity was also remarkable and praiseworthy. It was only 63,000 tonnes in 1951-52, in sharp contrast with 3.65 million tonnes of production in 1999-2000.

- In the case of capacity utilization, the fertilizer sector has improved considerably. In nitrogen fertilizer, it was only 18.82% in 1951-52 when the actual production was only 16,000 tonnes but, remarkably, capacity utilization rate increased to 82% in 2004-05 when production achieved an all-time high of 12.03 million tonnes.

Reasons and trends of growth of fertilizer industry in India

Location factors

- Raw Materials: Most of the industries are raw material oriented i.e. located where raw material is available.

- Naphtha is the most important and preferred feedstock accounting for over 70% of the installed capacity of nitrogen production. Naphtha is a by product of petroleum industry i.e. why many fertilizer industries near oil refineries. Most of the Napatha required by the industry is imported.

- Coal is another important constituent of the location factors. It is used both as fuel and raw material. Ammonia is required for nitrogenous fertilizer. The coal based fertilizer units are located at Ramagundem and Korba. The only lignite based unit in the country is located at Neyveli.

- Coke oven gas (COG), a by-product of iron & steel plants is also used as raw materials. This is the reason for many fertilizers plants located near Iron & Steel plants e.g. in Bhilai, Durgapur, Jamshedpur and Rourkela etc.

- Other important raw material includes Rock Phosphate used the manufacture of phosphoric fertilizers. About 90% of the requirement of phosphates is imported. The small phosphate deposits of commercial importance are confined to Singhbhum (Jharkhand), Vishakhapatnam (A.P.), and in some parts of Rajasthan.

- Sulphur is also an important raw material. There are no known large reserves of elemental sulphur in the country. However, some of the reserves of Sulphur is available in Tamil Nadu. Hydro-grade gypsum is used in large quantities for the manufacture of ammonium sulphate.

- Energy: It is another important determining factor, since the fertilizer industry is highly energy-intensive so many plants are located in areas where cheap energy is available i.e. Nangal Plant.

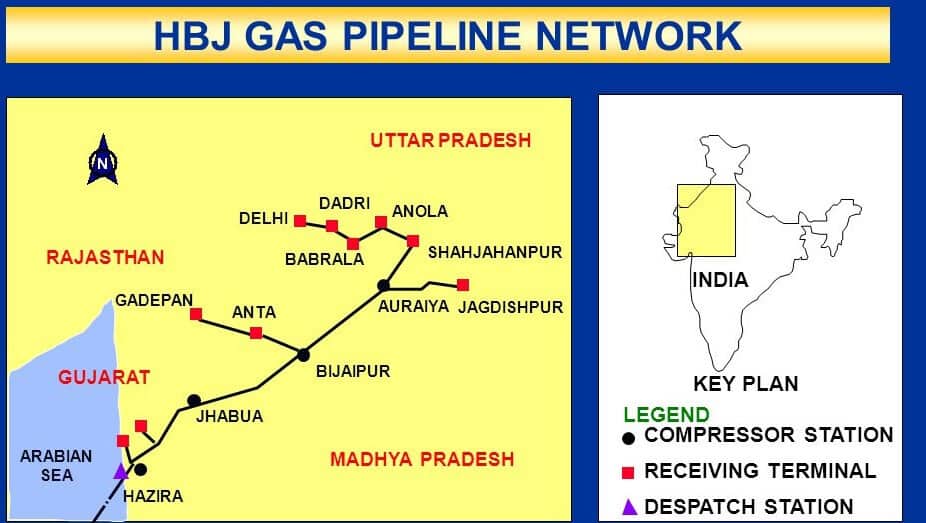

- Transportation: Since many raw materials needed by this industry have to be transported to the plant location and finished goods are to be transported to the consumption center and both of them are bulky so efficient transportation make the backbone of this industry. Ports offer an attractive location for the fertilizers industry that is why there are many port-based fertilizers plants. Gas pipelines e.g. HBJ has correspondence with fertilizer plants. Many fertilizer industries are located where there is a very high density of rail networks.

- Market: Apart from raw material, the market is also an important factor to be accounted

- in the location of these industries i.e. in Punjab and Uttar Pradesh the location of this industry is guided by market pull.

- Technology: Involvement of various chemical processes makes up gradation of technology imperative. Besides, fuel efficiency is very important owning to energy intensive nature of this industry.

- Government policy: It is the major factor deciding the localization of fertilizer industry besides the raw material vicinity. Location of Sindri fertilizer plant was a part of government policy. Further, Administered Price Mechanism earlier determined the prospects of this industry in India. International agreements in the form of increase or subsides regulate the consumption and in turn the growth of this industry. Fertilizer consumption has gone down in past few years because of abolishment of subsides.

- Capital: fertilizer industry involves huge capital viz-a-viz new materials, heavy machinery, transportation and new techniques. This factor has facilitated the location of industry in Gujarat-Maharashtra region.

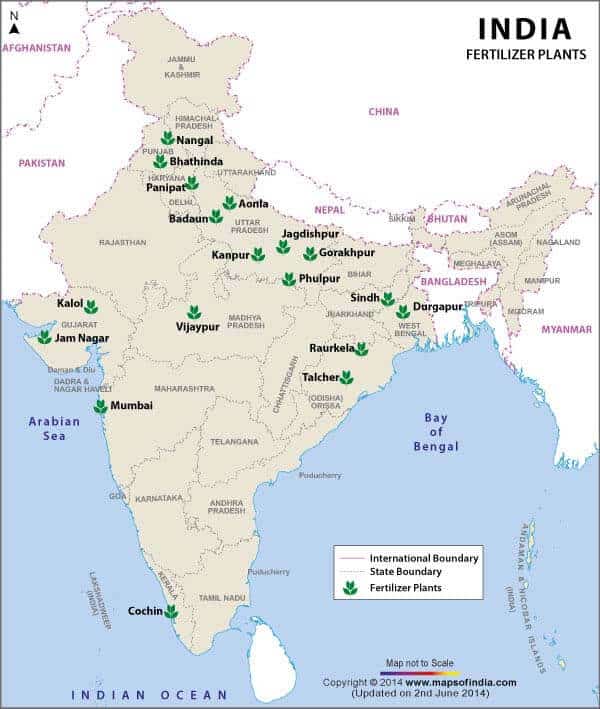

Distribution

- Fertilizer industry in India is concentrated in certain major regions of the country. This industry is mainly spread over 5 regions.

- Gujarat region

- Chhottanagpur region

- Tamil Nadu region

- North West region

- Uttar Pradesh region

- Gujarat Region:

- It includes Gujarat and Maharashtra and is the largest producer of fertilizer in the country.

- Petrochemical industries and oil refineries of this region produce Naphtha which is a basic raw material for nitrogenous fertilizer. Important centers are Vadodara, Kalol, Ahmedabad, Kandla and Trombay

- Chotanagpur plateau region and other Iron and Steel locations

- Here the fertilizer industries have cropped up due to proximity to Iron and Steel industries.

- The fertilizer industry of this region use byproducts of Iron and Steel industry as raw material that is Steel slug, coke, and lignite.

- Important centers are Jamshedpur, Rourkela, Durgapur, Burnpur, Sindri, Bhilai, etc

- Bhilai, Vizag, Mettur are other centers having fertilizer industry due to the presence of the Iron and Steel industry.

- Tamil Nadu Region

- It is the availability of Sulphur in the Tamil Nadu region that has propelled the growth of the industry in this region. Dispersal of fertilizer industry to South was important for its localization in this area.

- Important centers are Coimbatore, Neyveli, Alwaye (Kerala), Kochi (Kerala), Tuticorin, Ennore.

- North West region:

- This location has the advantage of huge market as it is the agriculturally most advanced region and market driven demand fuelled the growth of fertilizer industry in this region.

- Important centres are Bhatinda, Nangal (Punjab), Panipat (Haryana) and Delhi.

- Uttar Pradesh region

- This region became the hub of the fertilizer industry due to the availability of the mineral Phosphate

- Phosphatic fertilizer plants are located here i.e. Jagdishpur, Gorakhpur, Aonla, Shahjahanpur, Babrala etc.

- HBJ Pipeline

- This pipeline has been constructed by the Gas Authority of India Limited (GAIL) to transport gas and Neptha through the pipeline. It is 1,750 km long and connects Hazira in Maharashtra to Bijapur in M.P. and Jagdishpur in U.P.

- It carries 18 million cubic meters of gas every day to three powerhouses at Kawas (Gujarat), Anta (Rajasthan), and Auraiya (U.P.) and to six fertilizer plants at Bijapur, Sawai Madhopur,. Jagdishpur, Shahjahanpur, Aonla, and Babrala.

- Coal based Plants

- These plants are located in the close proximity of coal producing regions. Some of the plants are located in Korba, Talcher, Ramagundam and Neyveli.

Problems of fertilizer Industry

- General Problems:

- Raw Material Availability and Pricing: The Indian fertilizers industry faces some serious challenges in the form of availability and fluctuating prices of raw materials required to produce fertilizers. The primary cause of fertilizer price fluctuations is related to the supply and demand factors. India also faces a handicap due to lack of natural resources required to produce fertilizers. In case of urea, there is not enough natural gas available in the country. At times, increase in price of oil in international market has adverse impact on fertilizer industry.

- Government Policies: In order to make available the fertilizers to the farmers at low cost and to prevent the increase in cost of production of food crops the Govt. provided subsidies but now Governments are increasingly governed by international institution i.e. under WTO agreement there must be reduction in subsidies. This goes against the growth of this industry.

- Lesser expansion of Irrigation facilities and consequent low fertilizer consumption leads to low demand and therefore, restricts the growth of industry.

- Obsolete Technology: Most of the fertilizer industry operates under PSUs which are using decade old technology and thus making huge losses and also the competitive edge.

- Less expansion of irrigation facilities is also the reason for low demand hampering the growth of industry.

Prospects of the fertilizer industry

- Population: The increasing population and increasing demand for food security provides brighter prospects for fertilizer industry of higher growth.

- Food consumption: The pattern of food consumption and demand for varieties of food grains with improved attributes increases the role of fertilizers for their production.

- Fertilizer awareness: With increase in education, literacy and reach of digital means of communication, the awareness among farmers to use fertilizers has increased which in turn has increased its demand in the areas where use of fertilizer has not been common practice.

- Neem Coated urea:

- Neem has proven nitrification inhibition properties. It slows down the process of nitrogen release from urea (by about 10 to 15 percent) and reduces the consumption of the fertilizer.

- Government, on 24th March, 2015 made mandatory for all the indigenous producers of urea to produce 75%of their total production of subsidized urea as Neem Coated Urea.

- Subsequently, on 25th May 2015, Department of Fertilizers made it mandatory for all the domestic producers of urea to produce 100% as Neem Coated Urea with an extra MRP of 5% (of Rs. 5360/- per MT) to be charged by the fertilizer manufacturing entities from farmers. Entire quantity of indigenously produced urea and imported urea is being neem coated w.e.f 1st September, 2015 and 1st December, 2015 respectively.

Some other topics related to the fertilizer sector

- Nutrient Based Subsidy Scheme:

- Nutrient Based Subsidy (NBS) Programme for Fertilizers was initiated in the year 2010. The NBS deals with 22 grades of decontrolled fertilizers namely DAP, MAP, TSP, DAP Lite, MOP, SSP, Ammonium Sulphate and 15 grades of complex fertilizers.

- These fertilizers are provided to the farmers at the subsidized rates based on the nutrients (N, P, K & S) contained in these fertilizers.

- In a recent development, the Cabinet Committee on Economic Affairs has approved the proposal of the Department of Fertilizers for the continuation of the Nutrient Based Subsidy (NBS) till 2019-20.

- Joint Ventures Agreements in the Fertilizer Sector:

- The Government of India is encouraging fertilizers companies to establish joint ventures abroad in Countries which are rich in fertilizer resources for production facilities with buy back arrangements and to enter into long term agreement for supply of fertilizers and fertilizer inputs to India.

- Fertilizers companies need Natural Gas, Ammonia, Phosphoric Acid, Rock Phosphates, and Sulphuric Acid as raw materials for production of fertilizers.

Thank you very much 🙏🏼🙏🏼

i am very very grateful to you sir

lotus arise is now my primary preparation place for geography optional and graduation

thank you so much sir🙏🏼

Hazira port (Surat) is in Gujarat rather than in Maharashtra