In this article, You will read Aluminium Industry in India – for UPSC IAS.

Aluminium Industry

- Aluminium is the 2nd most important industry after the iron and steel industry.

- In the modern world the Aluminium is used in the production and distribution of electricity (being a good conductor of electricity), household utensils and electric appliances, manufacturing and aeroplanes, rail coaches, nuclear and defense accessories etc.

- The plant for obtaining Alumina from bauxite ore for aluminium plants is located near the cheap sources of energy i.e., electricity & hydel power supply.

- It is also the fastest-growing metal which has grown by nearly 20 times in the last sixty years (compared to 6 to 7 times for other metals).

- The Aluminium industry comprises two basic segments: upstream and downstream.

- The upstream sector produces primary Aluminium from raw materials via bauxite mining.

- The downstream sector comprises of processing of Aluminium into semi-finished Aluminium goods such as rods, bars, castings, forging, etc.

- India is the 2nd largest Aluminum Producer country in the world (in 2020).

- Bauxite mining sites in India are:

- Orissa: Orissa is the largest bauxite producing state accounting for more than half of the total production of India. The total recoverable reserves in the state are estimated at 1,370.5 million tonnes. The main bauxite belt is in Kalahandi and Koraput districts and extends further into Andhra Pradesh.

- Jharkhand: he reserves of all grades of recoverable bauxite in Jharkhand have been estimated at 63.5 million tonnes. These reserves are found in extensive areas of Ranchi, Lohardaga, Palamu and Gumla districts. Some bauxite is also found in Dumka and Munger districts. High grade ore occurs in Lohardaga and adjoining areas.

- Maharashtra: Maharashtra accounts for about 10 per cent of the total bauxite produced in India. The total recoverable reserves in the state have been estimated to be of the order of 87.7 million tonnes. The largest deposits occur in Kolhapur district capping the plateau basalts. Udgeri, Dhangarwadi, Radhanagari and Inderganj in Kolhapur district contain rich deposits with alumina content 52 to 89 percent.

- Chhattisgarh: Chhattisgarh produces more than 6 per cent bauxite of India. The Maikala range in Bilaspur, Durg districts and the Amarkantak plateau regions of Surguja, Raigarh and Bilaspur are some of the areas having rich deposits of bauxite.

- Madhya Pradesh: Amarkantak plateau area, the Maikala range in Shahdol, Mandla and Balaghat districts and the Kotni area of Jabalpur district are the main producers.

- Some bauxite is also found in Andhra Pradesh, (Vishakhapatnam, East Godavari and West Godavari), Kerala (Kannur, Kollam and Thiruvananthapuram), Rajasthan (Kota), Uttar Pradesh (Banda, Lalitpur and Varanasi), Jammu and Kashmir (Jammu, Poonch, Udhampur) and Goa.

- Bauxite (raw material) is bulky and for achieving economic production it is desirable to remove moisture & impurities before its ore is transported over long distances.

- For producing 1 tonne of aluminium, 6 tonnes of bauxite is required (which produces two tones of aluminium). The industry is power intensive as 30 to 35% of cost of production is accounted for by power. Thus availability of power at economic rates is necessary.

- There is shortage of primary metal to meet the demands of primary sectors.

- Domestic demand has increased more than 1 mm tonnes per year while production is around 0.5 m tones. Being electricity intensive industry, primary requisite of this industry is optimum sites which are not available in India.

Aluminium Production process

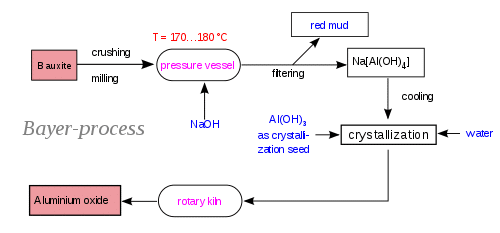

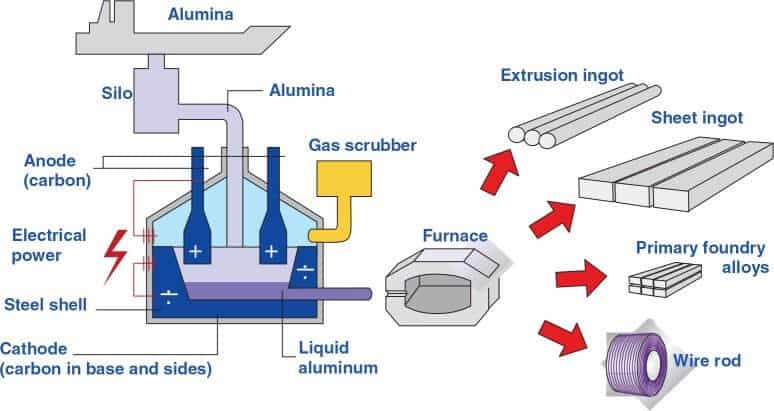

- Aluminium smelting is the process of extracting aluminium from its oxide, alumina, generally by the Hall-Héroult process. Alumina is extracted from the ore bauxite by means of the Bayer process at an alumina refinery.

- This is an electrolytic process, so an aluminium smelter uses huge amounts of electricity; smelters tend to be located close to large power stations, often hydroelectric ones, in order to reduce the overall carbon footprint.

Aluminium smelting plants in India

| Location | Name of company |

|---|---|

| Korba | Bharat Aluminium Co (BALCO) |

| Alupuram | Hindustan Aluminium Co. (HINDALCO) |

| Renukoot | Hindustan Aluminium Co. (HINDALCO) |

| Mettur | Madras Aluminium (MALCO) |

| Hirakud | Hindustan Aluminium Co. (HINDALCO) |

| Angul | National Aluminium Co. (NALCO) |

| Jharsuguda | Vedanta Aluminium Co. (VAL) |

Evolution of Aluminium Industries in India

- Among all the industries, aluminium industry is perhaps youngest. Aluminium was discovered only in 1886. Although bauxite, the principal ore of aluminium, is abundant all over the earth’s crust, its concentration of sizable amount is rare.

- First attempt to manufacture aluminium in India was started when Aluminium Corporation of India was formed in 1937. But its first venture to produce aluminium was delayed. The history of Aluminium industry in India can be traced in the following years:

- 1938: Indian Aluminium Company started its production at Allupuram in Kerala. To give a moral as well as financial boost to the industry, the Government announced in 1940 several facilities including import tax exemption and imposition of heavy duty on imported aluminium.

- 1942: Aluminium Corporation of India was able to start its production at Jaykeynagar in West Bengal.

- Second Five Year Plan: Aluminium plants setup during Second Five Year Plan were:

- Indian Aluminium Company (INDAL) – It started fabrication of sheets from imported alumina in 1943 and production of alumina from indigenous bauxite in 1948.

- Hindustan Aluminium Company (HINDALCO) – At Renukoot, UP- It was set up in 1958, it is the largest integrated primary producer of Aluminium and semifabricated products in India.

- Third Five Year Plan: Aluminium plants setup during Third Five Year Plan were:

- Madras Aluminium company (MALCO)- Operating since 1965 is located at Mettur (Tamil Nadu).

- Bharat Aluminium company ltd (BALCO) – It was established in 1965. Its unit at Korba Aluminium complex, Chhattisgarh obtains bauxite from Phutkapahar region Amarkantak.

- Indian Aluminium Company (INDAL) – It was established in 1970 at Belgam in Karnataka.

Aluminium Industries in India

- Hindustan Aluminum Company (HINDALCO) – It is located at Renukoot, UP. It was set up in 1958. It is the largest integrated primary producer of Aluminum and semifabricated products in India. All of its production facilities (alumina, Aluminum and fabricated products) are located at Rihand dam in Sonbhadra (UP). It is the biggest industrial enterprise in UP. This unit obtains bauxite from Lohardaga (Jharkhand) and Amarkantak (Chhattisgarh).

- Aluminum Corporation of India Ltd – Jaykaynagar, Asansol (West Bengal). In India, Aluminum corporation of India was 1st to produce aluminum from indigenous bauxite. It was registered in 1937 and started producing alumina in 1942 and that of aluminum in 1944. It possess its own coal mine, a thermal power plant, an alumina plant, a reduction plant, sheet rolling mill and a utensil manufacturing mill. Kolkata provides market.

- Bharat aluminum company ltd (BALCO) – It was established in 1965. Its unit at Korba Aluminum complex, Chhattisgarh obtains bauxite from Phutkapahar region Amarkantak. It’s another plant at Asansol i.e. Bidhanbag plant was taken over by Aluminum Corporation of India. Another plant of this company is at Ratnagiri (Maharashtra). After disinvestment the govt. has sold 51% of equity in BALCO to SERLITE Industries.

- National Aluminum Company (NALCO) – It came into being in 1981. It has set up integrated aluminum plant at Damanjodi (near Jeypur) in Koraput Dist of Orissa. It has state of art facilities and is largest bauxite – alumina – aluminum complex in India. The smelter with huge capacity has been set up at Angul in Dhenkanal dist. It exports more than 3.75 lakh tons of alumina overseas through Vishakhapatnam port. NALCO is the lowest cost producer of aluminum in the world, at present ranked among the top 10 global companies and is 2nd to HINDALCO in India.

- Madras aluminum company (MALCO)– Operating since 1965 is located at Mettur (Tamil Nadu). Power requirements are fulfilled by nearby Mettur dam.

- Indian Aluminum Company (INDAL) – It started fabrication of sheets from imported alumina in 1943 and production of alumina from indigenous bauxite in 1948. Its plants are located at Alupuram (Kerala). Another plant is at Hirakund in Orissa.

Problems of Aluminium Industry in India

- High cost of power & power shortage are the major hurdles in the development of Aluminium industry

- Production bottlenecks: Two factors affecting production are

- Dislocation of power supplies from grid system and.

- Total stoppage of power. Recent trends are that smelters have their own thermal power plants.

- Old technology in production – Smelter units which are decades old are more power consuming cost of production is higher.

- Vast deposits if bauxite recently discovered in east coast of India still lie unutilized.

- Controlled prices at which the industry sells aluminium to state electricity boards are un-remunerative & cause loss to the industry. The price controls extends to the commercial grade metal also. This erodes the profitability.

- High cost of input makes it difficult to Indian industries to compete in international market.

- Essential raw materials, like cryolite & fluoride are still imported.

- Barriers to entry

- Economies of scale – it are difficult to produce aluminium at low at a small scale since production cost decreases with the increase in scale (mainly power cost).

- Huge capital investment is required for setting up of Aluminium Industry. Small entrepreneurs cannot enter into Aluminium business easily.

- Time to set up Aluminium industry is high: Time to set up-a plant of the size of BALCO takes about 3-4 years to become operational.

- Control over bauxite mines – existing players already have the control over the known bauxite mines in the country, which leads to the manipulation of ore prices, negatively affecting the industry.

- Scarcity of power: Growth of Aluminium industry has been blocked by the power shortage which is one of the most essential components of production of Aluminium.

- Govt factors– The policies and bureaucratic processes such as environmental clearance, allotment of bauxite mines have also been responsible for dragging the industry behind.

- Land – Existing players can expand easily as setting up brown-field project is easier than a new green field project. Thus, the prospects for new players in the industry is getting diminished.

- International competition: India has got the best grade bauxite pre but the Aluminium production is not at par with Australia, Canada, France, USA etc.

- Non availability of cheap power is also one of the main reasons for the growth impediments of Industry in India.

- Strikes and labour unrests are also hurdles to the growth of Aluminium Industry in India.

*2nd most important metallurgical industry

*Gujrat ranks 2nd in Bauxite production ,you didnt mention it here .

https://lotusarise.com/bauxite-distribution-in-india-upsc/

China is leading (1st) in aluminium production.

very useful and informative blog for beginners like me thank you for sharing.

Very well written document with diagrams and data and current prospects of the industry.

Very Useful Information About Best Aluminium Industry in India

I’m Really Enjoyed it…