In this article, You will read Chemical and allied industries (Heavy inorganic chemical industry, Heavy organic chemical industry) – for UPSC IAS.

Chemical and Allied industries

- Chemical industries constitute one of the most vital and essential components of the country’s economy. This industry has undergone a great change during the last 3 decades and this change has become more perceptible after the liberalization of industrial policy in 1991. This sector constitutes the 4th largest set of industries after textiles, Iron and Steel, and Engineering industries.

- The rate of growth of this sector has been higher than the average growth rate of the Indian industry

- The chemical industry is central to the modern world economy, concentrating raw materials like oil, Natural Gas, water, minerals into thousands of products.

- The chemical industry uses chemical processes, reactions, and refining methods to produce a variety of products.

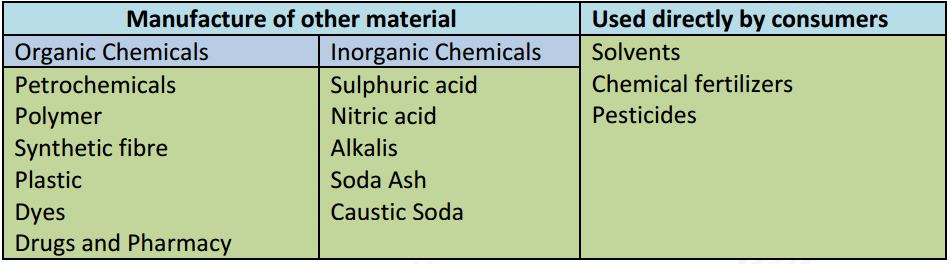

- Use of the products from the chemical industry is given in the table below:

- During the last decade the industry has been growing at the rate of 10% per annum

- Chemical industry in India is the 3rd largest producer in Asia and 6th largest in world. Indian Chemical industry is expected to double its share in global Chemical industry to 6% by 2021.

- Although Indian Chemical industry is a net importer with imports of US$ 19 billion compared to exports of $12.7 billion in 2015. Indian Chemical industry is expected to surge to US$ 226 billion by 2020 from US$ 147 billion in 2015.

- Chemical industry is studied under two heads:

- Heavy inorganic chemical industry

- Heavy organic chemical industry

Heavy inorganic chemical industry

- Sulphuric acid:

- It is an important ingredient for manufacturing fertilizer, synthetic fiber, plastics, paints, and dyestuff. Apart from these, it is also used in metallurgy, leather tanning, and oil refining.

- It is manufactured from sulfur which is not available in India in large quantity so 90% of sulphur has to be imported.

- About 80% of the production of Sulphuric Acid comes from Kerala, Tamil Nadu, Maharashtra, Gujarat, Madhya Pradesh, and Chhattisgarh, and West Bengal

- Nitric acid: The use and production of nitric acid is associated with fertilizer plants and explosives. Trombay unit of Fertilizer Corporation of India is the main producer.

- Alkalis industry:

- The manufacturing of alkalis requires heavy and weight-losing raw materials like common salt, limestone, and coal.

- This industry also requires cheap electricity in abundance, so the plants manufacturing alkalis tend to be located near the source of raw material, electricity, and market.

- This industry comprises soda ash, Caustic soda, Liquid chlorine, Calcium carbide, etc.

- Soda ash:

- It is used in the manufacturing of glass, paper, soaps, and detergents.

- The two chief raw materials used in the manufacturing of soda ash are sodium chloride and limestone, which are abundant in Gujarat.

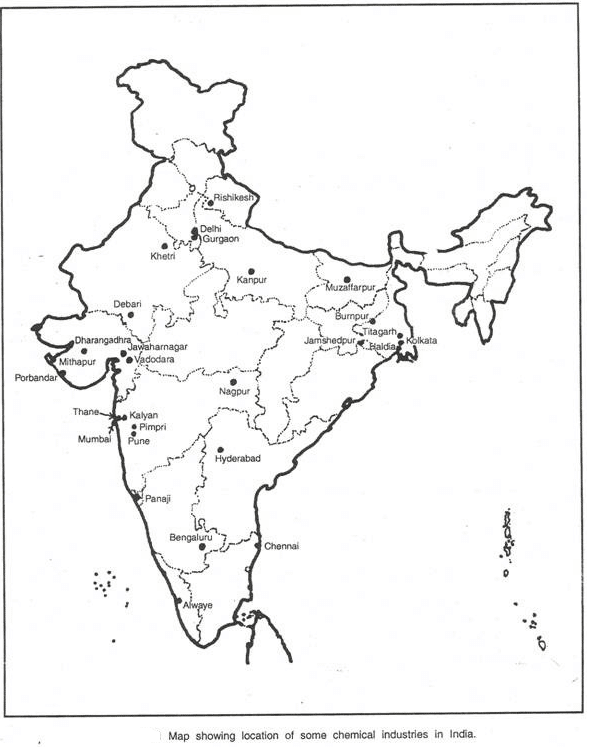

- Okha and Mithapur are important centers of manufacturing soda ash.

- Caustic soda:

- The caustic soda industry has grown steadily since the first plant, with a capacity of five tonnes a day. The first caustic soda factory was set up in Mettur in 1936.

- It meets the needs of industries like soap, detergents, textiles, and alumina. It’s a by-product, chlorine is an important chemical used in water treatment, paper, and pulp, soap, detergent, textile, etc.

- The basic raw material used for manufacturing caustic soda is a common salt. It is a highly power-intensive industry and the cost of power constitutes more than 2/3rd of the total cost of production of caustic soda. Major centers of production are Porbander, Mithapu, Thane, Kalyan, and Titagarh.

Heavy organic chemical industry

- Petrochemicals:

- Petrochemicals are those chemicals which are derived from crude petroleum during refining.

- These chemicals are used for manufacturing synthetic fiber, synthetic rubber, plastic, insecticide, drugs and pharmaceuticals.

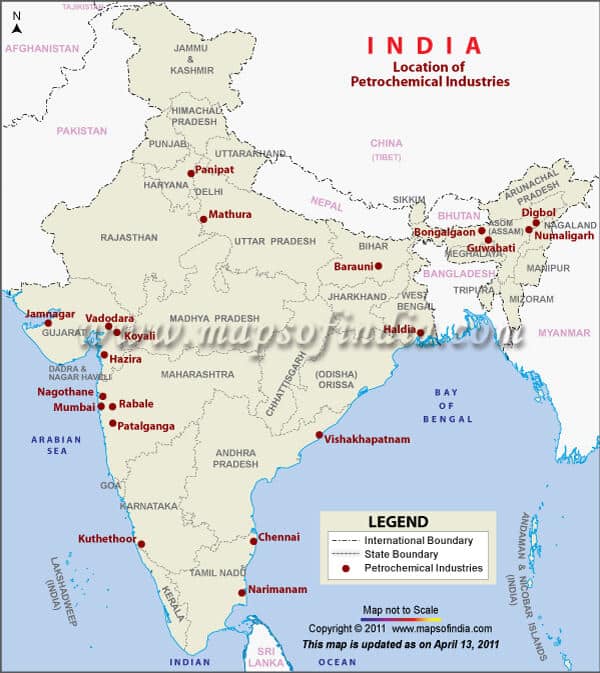

- Mumbai is the hub of Petrochemical industry. Cracker units are also located at Auraiya (UP), Jamnagar, Gandhar, Hazira (Gujarat), Ratnagiri (Maharashtra), Haldia (West Bengal) and Vishakhapatnam (Andhra Pradesh)

- The petrochemical industry is divisible into four sub groups:

- Polymer:

- It provides the basic raw material for the plastic industry. These are obtained in the process of refining crude oil in refineries. Polymer (polyethylene) if a widely used thermoplastic.

- Now India is a major exporter of polymer. The National Organic Chemical Industry limited (NOCIL), started the first naphtha-based chemical in Mumbai. Later several other companies were formed.

- Mumbai, Barauni, Mettur, Pimpri, and Rishra are major producers of plastic materials, the production of polymers in 2003-04 registered a growth of about 7.8%.

- There are about 20,000 units engaged in manufacturing various plastic products. Nearly, with a total investment of Rs 15,000 crore, the industry gives an annual turnover of Rs 25,000 crore. The industry has an average annual growth rate of 15% and employs three million people directly.

- Synthetic fibers:

- These are widely used for manufacturing a large variety of fabrics because of their special quality, dye-ability, workability, wash-ability, and resistance to wrinkles and shrinkage. Units of manufacturing nylon filament and polyester filament yarns are at Kota, Pimpri, Mumbai, Pune, Ujjain, Nagpur, and Udhana.

- Acrylic staple fiber is at Thane, Ghaziabad, Kota, and Vadodara.

- Elastomers:

- Elastomers are polymers that are having a viscosity as well as elasticity and therefore are known as visco-elasticity.

- The molecules of elastomers are held together by weak intermolecular forces, generally, they exhibit low Young’s modulus and high yield strength or high failure strain. They inherit the unique property of regaining original shape and size after being stretched to a great extent.

- Natural rubber, Polyurethanes, Neoprene, etc are examples of elastomers.

- Surfactant intermediate

- Surfactant, also called surface-active agent, a substance such as a detergent that, when added to a liquid, reduces its surface tension, thereby increasing its spreading and wetting properties.

- In the dyeing of textiles, surfactants help the dye penetrate the fabric evenly. They are used to disperse aqueous suspensions of insoluble dyes and perfumes.

- Polymer: