Sericulture

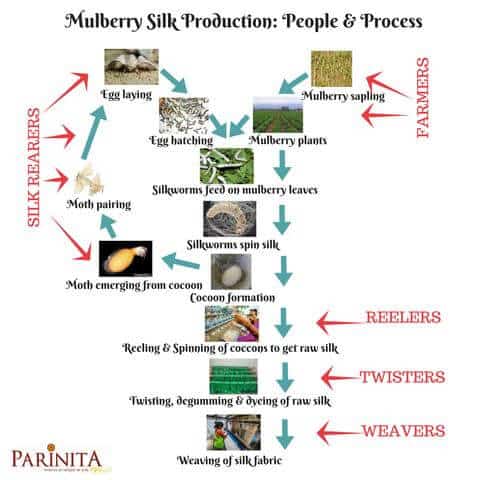

- Sericulture is the cultivation of silk rearing of silkworms. It is an agro-based industry. It involves the raising of food plants for silkworm, rearing of silkworm for production of cocoons, reeling and spinning of cocoon for production of yarn, etc. for value-added benefits such as processing and weaving.

- What is sericulture?

- Sericulture, or silk farming, is the rearing of silkworms for the production of raw silk.

- Amongst species of silkworms, Bombyx mori is the most widely used.

- Silk is known as the queen of textile and “BIOSTEEL” because of its strength.

Some Facts About Sericulture

- One hectare of Mulberry generates employment of about 12 man years and family members ranging in age between 18 to 60 years can engage themselves in various sericulture activities, such as, cultivation of food plants (Mulberry, castor etc., silkworm rearing, egg production, silk reeling, weaving etc.)

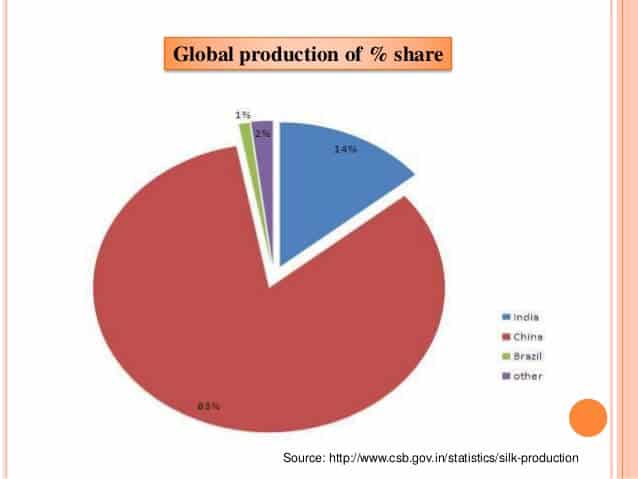

- India is the second largest producer of silk in the world after China.

- India has the distinction of producing all the four types of silk i.e. (a) Mulberry silk (91.7%); (b) Tasar silk (1.4%); (c) Eri silk (6.4%); and (d) Muga silk (.5%) which are produced by different species of silkworms.

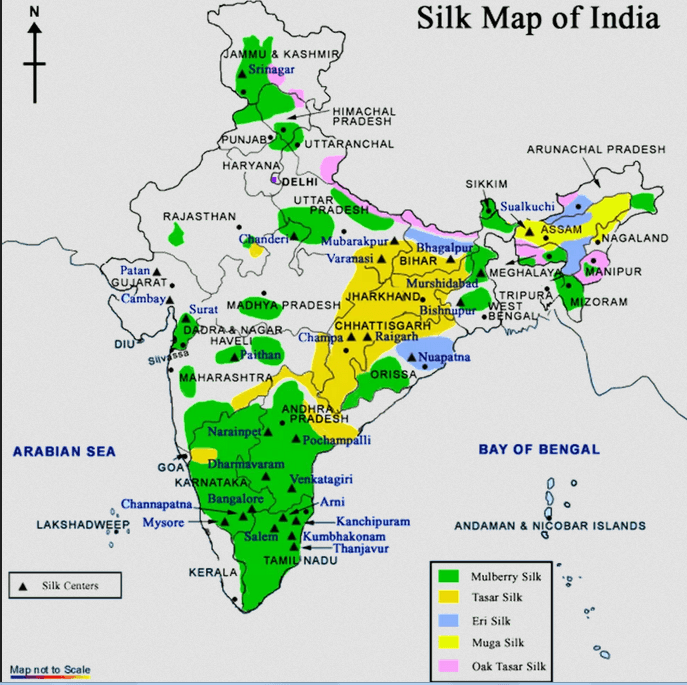

- Mulberry silk is produced extensively in the states of Karnataka, West Bengal and Jammu & Kashmir. Similarly, Tasar silk worms are reared traditionally by the tribes of Madhya Pradesh, Bihar, Orissa and Jharkhand; Muga and Eri silk are produced exclusively in Assam. The food plant of silkworms is Mulberry for producing Mulberry silk.

Sericulture – Historical Perspective

- China is said to be the origin of sericulture.

- The discovery of silk production by B.mori dates to about 2700 BC. Although archaeological records point to silk cultivation much earlier.

- In India the cultivation dates back to 140 AD.

- Later it was introduced to Europe, the Mediterranean and other Asiatic countries.

- Sericulture has become one of the most important cottage industries in a number of countries like China, Japan, India, Korea, Brazil, Russia, Italy and France.

- Today, China and India are the two main producers, together manufacturing more than 60% of the world production each year.

Central Silk Board

- Central Silk Board is a statutory body established under the Central Silk Board Act, 1948. It functions under the aegis of Union Ministry of Textile.

- It is a national organization for overall development of silk sector in India

- The Central Silk Board has been entrusted with the overall responsibility of developing silk industry covering the full gamut of sericulture activities in the country from development of food plants to silk cocoons for production of silk yarn including formation of policies governing Import & Export of silk.

- Central Silk Board is basically an R&D Organization. One of the important activities of the Central Silk Board is undertaking, assisting and encouraging scientific, technological and economic research in the Silk Sector

Sericulture – Stages of Production

- The silk moth lays eggs.

- When the eggs hatch, the caterpillars are fed mulberry leaves.

- When the silkworms are about 25 days old, they are 10,000 times heavier than when they hatched. They are now ready to spin a silk cocoon.

- The silk is produced in two glands in the silkworm’s head and then forced out in liquid form through openings called spinnerets.

- The silk solidifies when it comes in contact with the air.

- The silkworm spins approximately 1 mile of filament and completely encloses itself in a cocoon in about two or three days, but due to quality restrictions, the amount of usable silk in each cocoon is small. As a result, 5500 silkworms are required to produce 1 kg of silk.

- The silk is obtained from the undamaged cocoons by brushing the cocoon to find the outside end of the filament.

- The silk filaments are then wound on a reel. One cocoon contains approximately 1,000 yards of silk filament. The silk at this is known as raw silk. One thread consists of up to 48 individual silk filaments.

Production:

- In India, silk worms thrive on the leaves of mulberry, mahua, sal, ber, and kusum trees.

- In India, about 4.5 lakh hectares of area is under mulberry cultivation. Silk production is mainly confined to areas between 15 and 34 N latitudes. About 55 lakh people are engaged in this industry.

- The state of Karnataka is the largest producer of raw silk (65%) followed by Andhra Pradesh (170/0) West Bengal (8%), Tamil Nadu (5%), Assam (2.5%) and Jammu & Kashmir (1.2%). Limited quantity of mulberry silk is also produced in Arunachal Pradesh, Chhattisgarh, Himanchal Pradesh, Jharkhand, Kerala, Madhya Pradesh, Maharashtra, Manipur, Odisha, Punjab, Tripura, Uttarakhand and Uttar Pradesh.

- South India is the leading silk producing area of the country and is also known for its famous silk weaving enclaves like Kancheepuram, Dharmavaram, Arni, etc.

| State | Silk Centre |

|---|---|

| Andhra | Dharmavaram, Pochampalli, Venkatagiri, Narainpet, Karimnagar, Warangal, Mahbubnagar, Kurnool, Ongole, Adilabad, Hindupur |

| Assam | Sualkuchi |

| Bihar | Katihar and Bhagalpur |

| Gujarat | Surat, Cambay |

| Jammu & Kashmir | Srinagar |

| Karnataka | Bangalore, Anekal, Ilkal, Molakalmuru, Melkote, Kollegal, Tumkur, Doddaballapur, Mysore |

| Chattisgarh | Champa, Raigarh |

| Madhya Pradesh | Chanderi |

| Tamilnadu | Kanchipuram, Arni, Salem, Kumbhakonam, Tanjavur, Dharmapuram, Coimbatore, Tirunelveli |

| Uttar Pradesh | Varanasi |

| West Bengal | Bihnupur, Murshidabad, Birbhum, Malda, Bankura |

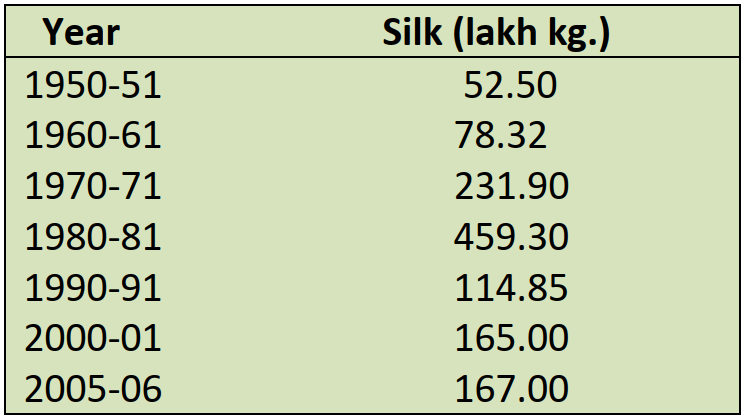

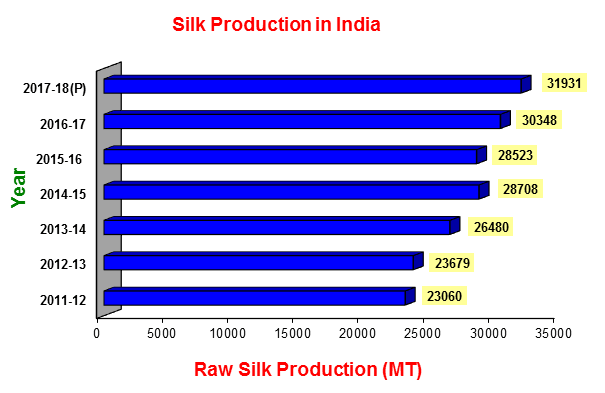

Trend in Raw Silk Production

- Silk production has a great future in India.

- India has the unique distinction of being the only country producing all the five known commercial silks, namely, Mulberry, Tropical Tasar, Oak Tasar, Eri and Muga, of which Muga with its golden yellow glitter is unique and prerogative of India.

- Mulberry sericulture is mainly practiced in five states namely Karnataka, Andhra Pradesh, Assam (Bodoland), West Bengal, Jharkhand and Tamil Nadu.

- North East has the unique distinction of being the only region producing four varieties of silk viz., Mulberry, Oak Tasar, Muga and Eri. Overall NE region contributes 18 per cent of India’s total silk production.

- India is the second largest producer of silk in the world. Among the four varieties of silk produced in 2016-17, Mulberry accounts for 71.8% (20,434 MT), Tasar 9.9% (2,818 MT), Eri 17.8% (5,054 MT) and Muga 0.6% (166 MT) of total raw silk production of 28,472 MT.

- The demand for superior quality bivoltine silk is increasing in India for domestic consumption as well as value added silk products for the export market. The Ministry of Textiles Government of India and Department of Sericulture in various states provide technical and financial assistance for enhancing the bivoltine silk production.

Sericulture – Opportunities

- Sericulture being cottage industry plays an important role in employment generation and poverty alleviation.

- It is one of the most profitable activities in rural sector.

- Availability of indigenous technology at low cost.

- Regular and quick returns.

- Large demand and popularity of hand woven silks in the West.

- Strong domestic demand coupled with use of silk garments on festive occasions.

- Large production gap to meet the domestic demand.

- Scope for establishing the large production units and organized sector.

- Effective utilization of the by-products will be more effective.

Recent steps taken by the Government to develop Sericulture in India:

- Integrated Scheme for the Development of Silk Industry for development of sericulture industry in various states including Tamil Nadu, focusing on intervention in critical areas such as Feed, Seed, Breed, Post Cocoon Technology and Capacity Building. The scheme has the following components:

- Research & Development, Training, Transfer of Technology & IT Initiatives.

- Seed Organization.

- Coordination and Market Development.

- Quality Certification system and Brand promotion & Technology up-gradation.

- Cold Storage facilities and Bivoltine grainages have been strengthened to produce quality Bivoltine silkworm seed.

- Silkworm Seed Act is being implemented to bring quality standards in silkworm seed production to improve the productivity and quality of silk.

- Central silk Board has developed latest technology packages, improved farm machineries, indigenous automatic reeling units and Vanya silk reeling and spinning units to reduce drudgery and improve quality and productivity of Vanya silk.

- Forest Conservation Act has been amended to treat non mulberry sericulture as forest based activity enabling the farmers to undertake Vanya silkworm rearing in the natural host plantation in the forests.

- Government of India through Central Sericulture training Institute of Central silk Board (CSB) has been providing the technical support for Cocoon sector, including the weaving sector.

- Introduction of all four varieties of silks to Handloom weavers.

- Introduction of spun silk as well yarn in Ikkats weaving.

- Conversion of traditional Patola fabrics into garments are some of the extension programme that has been carried that by Ministry of Textiles to promote silk infrastructure in the country.

awesome content

THANKU SOO MUCH,, AMAZING CONTENT