The primary instruments for space applications are satellites but they must be placed in carefully determined orbits in order to be useful. A variety of rocket systems have been developed for this purpose. Launch vehicles that send satellites and other spacecraft into space must be far more powerful than other types of rockets because they carry more cargo farther and faster than other rockets.

Indian Satellite Launch Vehicles

A launch vehicle is a rocket-powered vehicle used to transport a spacecraft beyond Earth’s atmosphere, either into orbit around Earth or to some other destination in outer space. The launch vehicles have been used to send crewed spacecraft, uncrewed space probes, and satellites into space since the 1950s.

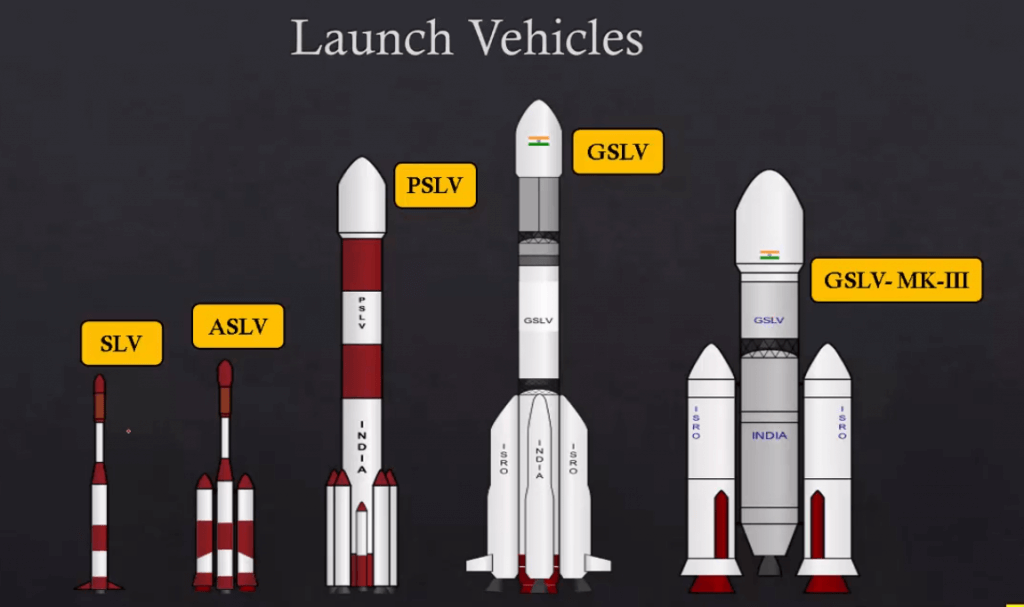

Launch Vehicles are used to transport and put satellites or spacecraft into space. In India, the launch vehicles development program began in the early 1970s. The first experimental Satellite Launch Vehicle (SLV-3) was developed in 1980. An Augmented version of this, ASLV, was launched successfully in 1992. India has made tremendous strides in launch vehicle technology to achieve self-reliance in the satellite launch vehicle program with the operationalization of Polar Satellite Launch Vehicle (PSLV) and Geosynchronous Satellite Launch Vehicle (GSLV).

Rocket propellant is the reaction mass of a rocket.

A propellant is a chemical mixture burned to produce thrust in rockets and consists of a fuel and an oxidizer.

Fuel is a substance that burns when combined with oxygen-producing gas for propulsion.

An oxidizer is an agent that releases oxygen for combination with a fuel. The ratio of oxidizer to fuel is called the mixture ratio.

Propellants are classified according to their state – liquid, solid, or hybrid.

Liquid Propellants: In a liquid propellant rocket, the fuel and oxidizer are stored in separate tanks and are fed through a system of pipes, valves, and turbopumps to a combustion chamber where they are combined and burned to produce thrust.

- Advantages: Liquid propellant engines are more complex than their solid propellant counterparts, however, they offer several advantages. By controlling the flow of propellant to the combustion chamber, the engine can be throttled, stopped, or restarted.

- Disadvantages: The main difficulties with liquid propellants are with oxidizers. Storable oxidizers, such as nitric acid and nitrogen tetroxide are extremely toxic and highly reactive, while cryogenic propellants being stored at low temperature and can also have reactivity/toxicity issues.

Liquid propellants used in rocketry can be classified into three types: petroleum, cryogens, and hypergolic.

- Petroleum fuels are those refined from crude oil and are a mixture of complex hydrocarbons, i.e. organic compounds containing only carbon and hydrogen. The petroleum used as rocket fuel is a type of highly refined kerosene.

- Cryogenic propellants are liquefied gases stored at very low temperatures, most frequently liquid hydrogen (LH2) as the fuel and liquid oxygen (LO2 or LOX) as the oxidizer. Hydrogen remains liquid at temperatures of -253 oC (-423 oF) and oxygen remains in a liquid state at temperatures of -183 oC (-297 oF).

- Hypergolic propellants and oxidizers that ignite spontaneously on contact with each other and require no ignition source. The easy start and restart capability of hypergolic make them ideal for spacecraft manoeuvring systems.

- Since hypergolic remain liquid at normal temperatures, they do not pose the storage problems like cryogenic propellants. Hypergolic are highly toxic and must be handled with extreme care. Hypergolic fuels commonly include hydrazine, monomethyl-hydrazine (MMH) and unsymmetrical dimethyl-hydrazine (UDMH).

Solid propellant: These are the simplest of all rocket designs. They consist of a casing, usually steel, filled with a mixture of solid compounds (fuel and oxidizer) that burn at a rapid rate, expelling hot gases from a nozzle to produce thrust. When ignited, a solid propellant burns from the center out towards the sides of the casing.

- There are two families of solids propellants: homogeneous and composite. Both types are dense, stable at ordinary temperatures, and easily storable.

- Composites are composed mostly of a mixture of granules of solid oxidizers, such as ammonium nitrate, ammonium dinitramide, ammonium perchlorate, or potassium nitrate in a polymer binding agent.

- Single-, double-, or triple-bases (depending on the number of primary ingredients) are homogeneous mixtures of one to three primary ingredients.

- Advantages: Solid propellant rockets are much easier to store and handle than liquid propellant rockets. High propellant density makes for compact size as well.

- Disadvantages: Unlike liquid-propellant engines, solid propellant motors cannot be shut down. Once ignited, they will burn until all the propellant is exhausted.

Hybrid propellant: These engines represent an intermediate group between solid and liquid propellant engines. One of the substances is solid, usually the fuel, while the other, usually the oxidizer, is liquid. The liquid is injected into the solid, whose fuel reservoir also serves as the combustion chamber.

- The main advantage of such engines is that they have high performance, similar to that of solid propellants, but the combustion can be moderated, stopped, or even restarted. It is difficult to make use of this concept for very large thrusts, and thus, hybrid propellant engines are rarely built.

Sounding Rockets

Sounding rockets are usually one or two-stage solid propellant rockets. They are primarily intended for probing the upper atmospheric regions using rocket-borne instrumentation. They also serve as platforms for testing prototypes of new components or subsystems intended for use in launch vehicles and satellites. The launch of the first sounding rocket US-made ‘Nike Apache’ from Thumba near Thiruvananthapuram, Kerala on November 21, 1963, marked the beginning of the Indian Space Programme.

In 1965, ISRO started launching a series of our own sounding rockets named Rohini from TERLS. RH-75, with a diameter of 75mm was the first truly Indian sounding rocket, which was followed by RH-100 and RH-125 rockets.

The sounding rocket program was indeed the bedrock on which the edifice of launch vehicle technology was built. The experience gained was of immense value in the mastering of solid propellant technology and allied systems of the launch vehicles. Several scientific missions with national and international participation have been conducted using the Rohini sounding rockets.

Operational Sounding Rockets

Currently, operational sounding rockets include three versions namely RH-200, RH-300-Mk-II, and RH-560-Mk-III. These cover a payload range of 8 to 100 kg and an apogee range of 80 to 475 km. The details are given below.

| Vehicle | RH-200 | RH-300-Mk-II | RH-560-MK-III |

| Payload (in kg) | 10.5 | 70 | 100 |

| Altitude (in km) | 75 | 120 | 550 |

| Purpose | Meterology | Middle atmospheric studies | Upper atmospheric studies |

| Launch Pad | Thumba | Thumba/SDSC-SHAR | SDSC-SHAR |

Operational sounding rockets are further divided in two groups:

- Satellite Launch Vehicle (SLV)

- Augmented Satellite Launch Vehicle (ASLV)

Satellite Launch Vehicle (SLV)

The Satellite Launch Vehicle (SLV) project was born out of the need for achieving indigenous satellite launch capability for communications, remote sensing and meteorology.

The Satellite Launch Vehicle-3 (SLV-3) was India’s first experimental satellite launch vehicle, which was an all solid, four-stage vehicle weighing 17 tonnes. It had a height of 22m and it was capable of placing 40 kg class payloads in Low Earth Orbit (LEO).

The first experimental flight of SLV3, in August 1979, was only partially successful. The next launch on July 18, 1980, from Sriharikota Range (SHAR), successfully placed Rohini satellite, RS-1, into orbit, thereby making India the sixth member of an exclusive club of space-faring. Apart from the July 1980 launch, there were two more launches held in May 1981 and April 1983, orbiting Rohini satellites carrying remote sensing sensors.

The successful culmination of the SLV-3 project showed the way to advanced launch vehicle projects such as the Augmented Satellite Launch Vehicle (ASLV), Polar Satellite Launch Vehicle (PSLV), and the Geosynchronous Satellite Launch Vehicle (GSLV).

Augmented Satellite Launch Vehicle (ASLV)

Augmented Satellite Launch Vehicle (ASLV) was developed to act as a low-cost intermediate vehicle to demonstrate and validate critical technologies. With a lift-off weight of 40 tonnes, the 23.8 m tall ASLV was configured as a five-stage, all-solid propellant vehicle, with a mission of orbiting 150 kg class satellites into 400 km circular orbits. The strap-on stage consisted of two identical 1m diameter solid propellant motors, Under the ASLV program, four developmental flights were conducted.

- The first developmental flight took place on March 24, 1987,

- and the second on July 13, 1988.

- ASLV-D3 was successfully launched on May 20, 1992, when SROSS-C (106 kg) was put into an orbit of 255 x 430 km.

- ASLV-D4 launched on May 4, 1994, orbited SROSS-C2 weighing 106 kg. It had two payloads, Gamma Ray Burst (GRB) Experiment and Retarding Potential Analyser (RPA), and functioned for seven years.

ASLV provided valuable inputs for further development.

Polar Satellite Launch Vehicle (PSLV)

Polar Satellite Launch Vehicle (PSLV) is the third generation launch vehicle of India. It is the first Indian launch vehicle to be equipped with liquid stages. PSLV has four stages using solid and liquid propulsion systems alternately.

After its first successful launch in October 1994, PSLV emerged as the reliable and versatile workhorse launch vehicle of India with 39 consecutively successful missions by June 2017.

During the 1994-2017 period, the vehicle has launched 48 Indian satellites and 209 satellites for customers from abroad. Besides, the vehicle successfully launched two spacecraft – Chandrayaan-1 in 2008 and Mars Orbiter Spacecraft in 2013 – that later traveled to Moon and Mars respectively.

PSLV earned its title “the workhorse of ISRO” through consistently delivering various satellites to Low Earth Orbits, particularly the IRS series of satellites.

It can take up to 1,750 kg of payload to sun-synchronous polar orbits of 600 km altitude. Due to its unmatched reliability, PSLV has also been used to launch various satellites into Geosynchronous and Geostationary orbits, like satellites from the IRNSS constellation. The PS4 is the uppermost stage of PSLV, comprising of two Earth storable liquid engines.

Indian Regional Navigation Satellite System (IRNSS)

Indian National Satellite System (INSAT)

Geostationary Satellite (GSAT)

Launched Missions → Chandrayaan-1, Mars Orbiter Mission, Space Capsule Recovery Experiment, IRNSS, Astrosat.

Vehicle Variants and Launch Capability

- PSLV-Generic

- PSLV-Core Alone

- PSLV XL

PSLV-Generic

- No. of Solid Strap-ons : Six (9T)

- Payload capability to SSPO (600 km) : 1550 kg

PSLV – Core Alone

- No. of Solid Strap-ons: NIL

- Payload capability to SSPO (600 km) : 1100 Kg

PSLV XL

- No. of Solid Strap-ons: Six (12T)

- Payload capability o SSPO (600 Km) : 1700 kg

- Payload capability o sub GTO (284 x 20650 km) 1425 Kg

Geosynchronous Satellite Launch Vehicle (GSLV)

Geosynchronous Satellite Launch Vehicle (GSLV) is capable of placing 2 ton class of satellites like the INSAT and GSAT series of communication satellites into Geosynchronous Transfer Orbit (GTO).

Geosynchronous Satellite Launch Vehicle Mark-II (GSLV Mk II) is the largest launch vehicle developed by India, which is currently in operation. This fourth-generation launch vehicle GSLV Mk-II has the capability to launch satellites of lift-off mass of up to 2,500 kg to the GTO and satellites of up to 5,000 kg lift-off mass to the LEO.

GSLV Mk-II is a 49 m tall, three stage vehicle with a lift-off mass of 416 ton.

- The first stage comprises of a S139 solid booster with four liquid strap-on motors, each weighing 40 tons.

- The second stage (GS2) is a liquid engine carrying 37.5 tons of liquid propellant.

- The third stage is the indigenously built Cryogenic Upper Stage (CUS) which uses typically 15 tons of cryogenic propellants (Liquid Hydrogen (LH2) as fuel and Liquid Oxygen (LOX) as Oxidiser).

Vehicle Versions

- GSLV Mk-I : (Russian Cryogenic)

- GSLV Mk-II : (Indigenous Cryogenic)

- GSLV Mk-III : (Indigenous Cryogenic)

Cryogenic rocket engine – Fuel or oxidizer (or both) is gases liquefied and stored at very low temperatures.

Cryogenic Rocket

- A cryogenic rocket engine is a rocket engine that uses a cryogenic fuel or oxidizer, that is, its fuel or oxidizer (or both) are gases liquefied and stored at very low temperature.

- A Cryogenic rocket stage is more efficient and provides more thrust for every kilogram of propellant it burns compared to solid and earth-storable liquid propellant rocket stages. Specific impulse achievable with cryogenic propellants (liquid Hydrogen and liquid Oxygen) is much higher compared to earth storable liquid and solid propellants, giving it a substantial payload advantage.

- Oxygen liquefies at -183 deg C and Hydrogen at -253 deg C also entails complex ground support systems like propellant storage and filling systems, cryo engine and stage test facilities, transportation and handling of cryo fluids, and related safety aspects.

Difference Between PSLV & GSLV

PSLV (Polar satellite launch vehicle)

- First launch 1993

- Can carry up to 1425 kg satellite in GTO

- Can carry up to 1750 kg in LEO orbit

- For launching Indian remote sensing satellites (IRS)

- Used for Chandrayaan & Mars Mission

- four stages propellant using solid and liquid propulsion systems alternately

GSLV (Geosynchronous satellite launch vehicle)

- First launch 2001

- Can carry up to 2500 kg satellite in GTO orbit

- Can carry up to 5000 kg satellite in LEO orbit

- Developed mainly for launching Indian National satellites (INSAT)

- The next version is GSLV MK-3

- Three stages propellant using solid, liquid & cryogenic propulsion in order

Geosynchronous Satellite Launch Vehicle MK3 (GSLV Mk 3)

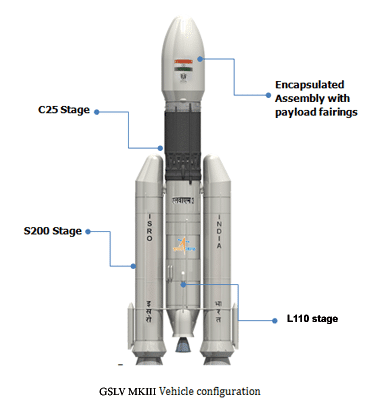

The Geosynchronous Satellite Launch Vehicle Mark III (GSLV MkIII) also known as LVM3, is the next generation launcher being developed by ISRO for achieving self-reliance in the launch of 4 ton class of communication satellites to Geosynchronous Transfer Orbits (GTO).

GSLV Mk-III is a 43.43 m tall three stage vehicle with a lift-off mass of 640 tones.

The launcher is designed to be a versatile launcher to launch payloads to other orbits as well and will have a payload capability in excess of 10 tons to Low Earth Orbits (LEO). Once GSLV-MkIII becomes operational, India would be able to dispense the procured launches for 4-ton class communication satellites.

The powerful cryogenic stage of GSLV Mk III enables it to place heavy payloads into Low Earth Orbits of 600 km altitude. The Cryogenic Upper Stage (C25) is powered by CE-20, India’s largest cryogenic engine, designed and developed by the Liquid Propulsion Systems Centre. GSLV Mk III uses two S200 solid rocket boosters to provide the huge amount of thrust required for lift off. The S200 was developed at Vikram Sarabhai Space Centre.

It will allow India to achieve complete self-reliance in launching satellites as –

- It will be capable of placing 4-tonne class Geosynchronous satellites into GTO

- It will be capable of placing 8-tonne class satellites into LEO

Significance of GSLV MK3

- GSLV will cost just one-third of the money spent on foreign agencies, which will reduce satellite launch cost as well as will save Forex

- It will enhance India’s capability to be a competitive player in the multimillion-dollar commercial launch market. It will help in earning foreign exchange.

- The GSLV will help ISRO put heavier communication satellites of GSAT class into orbit.

- Reduction of dependence on foreign agencies gives a strategic boost in this high tech sector

Small Satellite Launch Vehicle

- The Indian Space Research Organisation (ISRO) has developed the much awaited Small Satellite Launch Vehicle (SSLV).

- Till now the small satellites were being launched along with the bigger ones through PSLV (Polar Satellite Launch Vehicle) which was adding an unprecedented amount of waiting time for the small satellite developers.

- The SSLV seeks to serve the rapidly growing market for the launch of small satellites into the LEO (Earth’s low orbits) which has emerged in recent times to serve the requirements of the developing nations, universities/institutions for small satellites, and private firms.

- SSLV is a three-stage vehicle and has a capability to launch up to 500 kg satellite mass into 500 km Low Earth Orbit (LEO) and 300 kg to Sun Synchronous Orbit (SSO).

- The launch vehicle uses solid fuel in all its stages of flight.

- It is perfectly suited for launching multiple microsatellites at a time and supports multiple orbital drop-offs.

- Manufacturing of SSLV is the responsibility of the commercial arm of ISRO i.e. NSIL (New Space India Limited).

- SSLV is ISRO’s lightest launch vehicle, weighing around 110 tons.

- Contrary to PSLV’s 70 days time to get integrated, the SSLV takes only 72 hours.

- SSLV needs only 6 people to integrate it.

- The vehicle also features both vented and closed interstage.

- The key features of SSLV are low cost, with low turn-around time, flexibility in accommodating multiple satellites, launch on demand feasibility, minimal launch infrastructure requirements, etc.

Reusable Launch Vehicle – Technology Demonstrator (RLV-TD)

Reusable Launch Vehicle – Technology Demonstrator (RLV-TD) is one of the most technologically challenging endeavours of ISRO towards developing essential technologies for a fully reusable launch vehicle to enable low-cost access to space. The configuration of RLV-TD is similar to that of an aircraft and combines the complexity of both launch vehicles and aircraft.

The winged RLV-TD has been configured to act as a flying testbed to evaluate various technologies, namely, hypersonic flight, autonomous landing, and powered cruise flight. In the future, this vehicle will be scaled up to become the first stage of India’s reusable two-stage orbital launch vehicle.

RLV-TD consists of a fuselage (body), a nose cap, double delta wings, and twin vertical tails. It also features symmetrically placed active control surfaces called Elevons and Rudder. This technology demonstrator was boosted to Mach no: 5 by a conventional solid booster (HS9) designed for low burn rate. The selection of materials like special alloys, composites, and insulation materials for developing an RLV-TD and the crafting of its parts is very complex and demands highly skilled manpower. Much high technology machinery and test equipment were utilized for building this vehicle.

Objectives of RLV-TD:

- Hypersonic aero thermodynamic characterisation of wing body;

- Evaluation of autonomous Navigation, Guidance and Control (NGC) schemes;

- Integrated flight management;

- Thermal Protection System Evaluation;

Achievements:

RLV-TD was successfully flight tested on May 23, 2016, from SDSC SHAR Sriharikota validating the critical technologies such as autonomous navigation, guidance & control, reusable thermal protection system, and re-entry mission management.

Scramjet Engine

The satellites are launched into orbit by multi-staged satellite launch vehicles that can be used only once i.e. they are expendable. These launch vehicles carry oxidiser along with the fuel for combustion to produce thrust. Launch vehicles designed for one time use are expensive and their efficiency is low because they can carry only 2-4% of their lift-off mass to orbit. Thus, there is a worldwide effort to reduce the launch cost.

Nearly 70% of the propellant (fuel-oxidiser combination) carried by today’s launch vehicles consists of oxidiser. Therefore, the next generation launch vehicles must use a propulsion system which can utilise the atmospheric oxygen during their flight through the atmosphere which will considerably reduce the total propellant required to place a satellite in orbit.

Also, if those vehicles are made re-usable, the cost of launching satellites will further come down significantly. Thus, the future re-usable launch vehicle concept along with air-breathing propulsion is an exciting candidate offering routine access to space at far lower cost.

Considering the strategic nature of air-breathing technology which has the potential to bring a significant shift in the launch vehicle design, worldwide efforts are on to develop the technology for air breathing engines. Ramjet, Scramjet and Dual Mode Ramjet (DMRJ) are the three concepts of air-breathing engines which are being developed by various space agencies.

A ramjet is a form of air-breathing jet engine that uses the vehicle’s forward motion to compress incoming air for combustion without a rotating compressor. Fuel is injected in the combustion chamber where it mixes with the hot compressed air and ignites. A ramjet-powered vehicle requires an assisted take-off like a rocket assist to accelerate it to a speed where it begins to produce thrust.

Ramjets work most efficiently at supersonic speeds around Mach 3 (three times the speed of sound) and can operate up to speeds of Mach 6. However, the ramjet efficiency starts to drop when the vehicle reaches hypersonic speeds.

A scramjet engine is an improvement over the ramjet engine as it efficiently operates at hypersonic speeds and allows supersonic combustion. Thus it is known as Supersonic Combustion Ramjet or Scramjet.

A dual-mode ramjet (DMRJ) is a type of jet engine where a ramjet transforms into a scramjet over Mach 4-8 range, which means it can efficiently operate both in subsonic and supersonic combustor modes. An important development in ISRO’s Air Breathing Propulsion Project (ABPP) occurred on August 28, 2016, which was the successful flight testing of its Scramjet.

The first experimental mission of ISRO’s Scramjet Engine towards the realisation of an Air Breathing Propulsion System was successfully conducted from Satish Dhawan Space Centre SHAR, Sriharikota on August 28, 2016. With this flight, critical technologies such as ignition of air breathing engines at supersonic speed, holding the flame at supersonic speed, air intake mechanism and fuel injection systems have been successfully demonstrated. The Scramjet engine designed by ISRO uses Hydrogen as fuel and the Oxygen from the atmospheric air as the oxidiser. The August 28 test was the maiden short duration experimental test of ISRO’s Scramjet engine with a hypersonic flight at Mach 6.

ISRO’s Advanced Technology Vehicle (ATV), which is an advanced sounding rocket, was the solid rocket booster used for this test of Scramjet engines at supersonic conditions. Some of the technological challenges handled by ISRO during the development of Scramjet engine include the design and development of Hypersonic engine air intake, the supersonic combustor, development of materials withstanding very high temperatures, computational tools to simulate hypersonic flow, ensuring performance and operability of the engine across a wide range of flight speeds, proper thermal management and ground testing of the engines. India is the fourth country to demonstrate the flight testing of a Scramjet Engine.

good article

Nice.. informative..

Quality content

its so useful for me… i havent seen any free articulate like this for upsc perspectives..thankyou so much

Great …really helpful

Very nice and informative

are these notes updated periodically?