In this article, You will read Jute Textile Industry in India – for UPSC (Industry – Geography of India).

Jute Textile Industry

- Jute Textile Industry is one of the major Industries in the Eastern India, particularly in West Bengal. This is the second important textile industry after cotton textile.

- India is one of the largest producer of product, the production process in the Jute Industry goes through a variety of activities, which include cultivation of raw jute, processing of jute fibres, spinning, weaving, bleaching, dyeing, finishing and marketing of both, the raw jute and its finished products.

- Thus, Jute supports around 40 Lakh farm families and provides direct employment to 2.6 Lakh Industrial Workers and 1.4 Lakh in the tertiary sector and also earns valuable foreign exchange through exports.

Growth and Development

- Jute manufacturing existed as a handloom industry but the large-scale industry started in 1855 in Rishra near Calcutta.

- Then power looms were started and spinning, as well as weaving, was undertaken. It was an export-oriented industry and it made rapid progress.

- The partition of the country in 1947 created a peculiar problem for jute industry. Almost all mills remained in India but 80% of jute producing area went to erstwhile East Pakistan.

- The import of raw material from East Pakistan was cut off due to the political differences between the two countries.

- A consistent effort to increase the area under jute cultivation was able to correct the situation later.

- It is traditionally in an export-oriented industry and its survival largely depends upon its export performance. The rise and fall of the industry is closely linked with the demand for goods in the international and national markets.

- India had produced 102 lakh bales of jute in 2011-12 Crop year (July -June). One bale of jute is equal to 332.5 kg.

Growth and distribution

- Consistence efforts to increase jute area helped in improving the situation. However, jute cultivation has fluctuated due to

- Dependence on monsoons: Jute cultivation depends largely on monsoon which is erratic in nature this affecting production of jute.

- Govt policies: Jute industry is predominantly dependent on Government sector which purchases jute products more than Rs. 5,500 crore every year. Any change in policy affects the industry to large extent.

- Delay in announcing support prices: The industry earns a business of around Rs. 10,000 crore by selling its entire produce to FCI (Food Corporation of India), sugar mills, co-operatives and in the Indian market apart from the export. FCI makes a bulk purchase of almost 35-40 per cent of jute mills produce. With the delay in announcing minimum support prices (MSP), the industry has been suffering from major cash crunches. The MSP is the rate at which the government buys grains from farmers. The reason behind the idea of MSP is to counter price volatility of agricultural commodities due to the factors like variation in their supply, lack of market integration and information asymmetry.

- Jute textile production has also been fluctuating

- Labour unrest: Jute industry suffers a lot from different political interference, labour problem leading to challenging the sustainability of the jute industry.

- Fluctuating demand: Jute industry faces stiff competition with the synthetic industry for similar packaging material, as the synthetic material is much cheaper in nature.

- Non–availability of raw material: Most of the jute-producing areas went to Bangladesh (erstwhile East Pakistan) resulting in an acute shortage of raw jute. Although successful efforts have been made to increase the supply of raw jute since Independence, it still falls short of our current requirements.

Location factors

- Jute industry depends on:

- Availability of quality jute: The Ganga-Brahmaputra delta grows about 90 percent of India’s jute and provides raw material to jute mills.

- Transportation: Cheap water transportation is available in the Ganga-Brahmaputra delta region. The area is also served by a network of roads and railways.

- Labour: High density of population is required for abundant cheap labour.

- Water: Abundant water is required for processing, washing, and dyeing jute.

- Market: Big capitalists are living in and around Kolkata and the High density of population in West Bengal makes the easy flow of capital in this industry and provides a robust market.

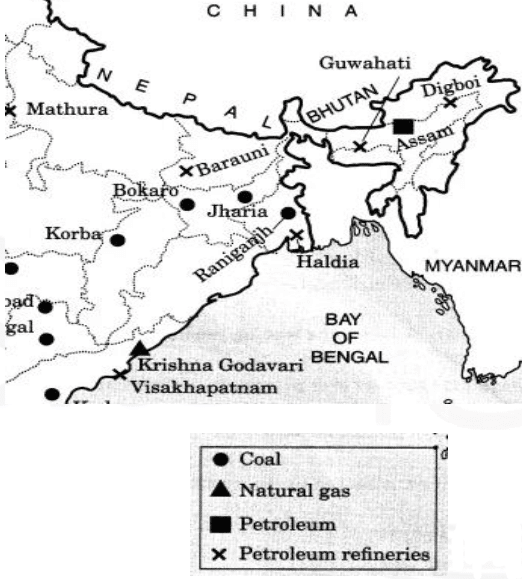

- Power: Coal is obtained from Raniganj fields which are hardly 200 km away from Ganga-Brahmputra region.

- In India, the jute industry is highly localization and concentrated in specific regions.

Location Factor of Jute Industry (mainly around West Bengal)

- Water:

- Flowing water in abundant quantity is required, which is provided by Hoogly River.

- Water is also required for Retting, Washing, dyeing etc.

- Transportation:

- Hooghly River provides cheap transportation for the industry.

- A dense network of road and railways has also helped in flourishing jute industry in Eastern region.

- Raw material

- Ganga Brahmaputra delta grows about 90% of India’s jute production

- India now tops the production of raw jute.

- Shortage of raw jute due to political differences with Bangladesh led to a relentless campaign to increase production of raw jute by increasing area in Brahmaputra Valley, West Bengal, Tarai and E. Coastal Plains and all regions around Calcutta.

- New hybrid varieties like JRO – 632, JRO – 753 are being grown, with better outputs.

- Climate

- Humid climate suited to jute cultivation

- Humid climate is very convenient for spinning and weaving of raw jute.

- Labour

- It is a labour intensive industry: large man power is required for jute cultivation, processing, dyeing etc.

- High density of population in west Bengal, Bihar and Eastern U.P provide cheap labour for industry.

- 4 million farmers, mostly small and marginal and 2 lakh workers are engaged in jute cultivation and production.

- Coal

- Raniganj field within 200 KM distance provide coal to the industry.

- DVC also avails ready power to the industry.

- Port

- Calcutta port serves this region for import of machinery and other material and export of finished material abroad.

- The riverine nature of the port has facilitated easy mobility of various products.

- Market

- Rich hinterland of Calcutta and industrial development around it provide a ready market for the jute industry.

- Development of the sugar industry in neighboring U.P and Bihar also boosted demand for gunny bags. Export other countries through Calcutta port in the vicinity also provided a good market. India is second in the export of jute goods and tops the list in production.

- Govt. Issues an order under jute packaging materials, 1987 under which a mandatory percentage of packaging of sugar (50%) and food grains (60%) in jute bags also helped the industry.

- Capital and banking

- Big capitalists in and around Calcutta ensure the easy flow of capital in this industry.

- Agglomeration has also ensured banking and insurance facilities in this region.

- Historical advantages

- Last but not least, rarely start of the industry by East India Company in this region enjoys the growth in letter periods.

- The needs of jute bags in industrializing Europe during 19th century gave an impetus to the jute industry. British enterprise and capital played a great role in initial development and expansion.

- Due to these factors, the Jute industry is largely confined to West Bengal in general and Hugli in particular.

- After independence, there has been some limited dispersion of the industry, are 4 other regions of Jute:

- North East India – here the industry has emerged principally due to favourable environmental conditions.

- North–east plains of Bihar – here rainfall and soil conditions are favourable.

- Tarai regions of UP

- Eastern Coastal region

- There has been some dispersion, due to increasing demand from the sugar industry in UP and cement industry MP. Also, with the increasing trend of mixing jute with other fibres, dispersion of jute industry has been to areas where there is the availability of such fibre e.g. Mesta grown in South India especially in Andhra Pradesh.

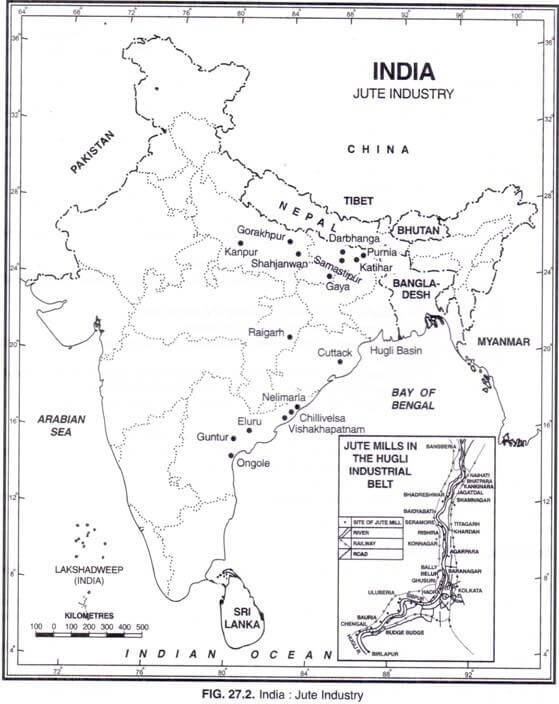

- Apart from WB, there are jute mills at Guntur Vishakapatnam and in Andhra Pradesh, Kanpur, Gorakhpur in UP, Purnea, Katihar, Samastipur, Darbhanga, Gaya in Bihar, Raigarh in Chhattisgarh, and Cuttack in Orissa, Assam, and Tripura also have one mill each.

Distribution of Jute Industry

- West Bengal has the largest concentration of the jute industry accounting for more than 80% of production and mills.

- Dispersal of the industry has taken place westwards with Andhra accounting for another 10% and rest in UP and Bihar.

- Most of the jute mills are within a radius of 64 KM around Calcutta; confined in a narrow belt 3 KM wide and 100 KM long along Hugli River.

- In addition to West Bengal, jute mills are also located at Guntur, Vishakhapatnam and Nelimarla, Chellivelsa, Eburu and Ongole in Andhra Pradesh; Kanpur, Shahjanwan and Gorakhpur in Uttar Pradesh; Purnea, Katihar, Samastipur, Darbhanga and Gaya in Bihar; Raigarh in Chhattisgarh and Cuttack in Orissa. Assam and Tripura also have one jute mill each.

Problems of Jute industry

- Overall demand of jute in international market is reducing.

- There is a tough competition from synthetic packing materials of advanced countries of Europe and N. America. Therefore market of jute goods is shrinking. These products are durable and cheaper.

- Within the jute goods market, Bangladesh mills are competing along with China with better quality goods.

- Bulk handling practices in US, Argentina, Canada, Japan and Europe have decreased demand of jute.

- Cost of Indian jute product is comparatively higher.

- Availability of local fibres like Mesta (especially in Andhra Pradesh) etc, have reduced jute demand.

- Jute industry is facing stiff competition synthetic packing material.

- This specific industry is also using the age-old machinery to produce jute yarns and fabrics (except 2-3 countable industry). Due to the use of very old primitive machinery, the efficiency of the machines is not up to the mark (in an average within 80 per cent). Due to frequent breakdowns, defective and inferior quality products are being made. No modernization has been made in machinery development and automation. New mills in Bangladesh are producing better quality goods which are diminishing the competitiveness of Indian mills.

- Infrastructural bottlenecks, power, transportation, and capital also pose several threats to the sustainability of Jute industry.

- Raw material-Even after substantial increase in area and yield in jute production, India falls short of requirement which lead to underutilization of installed capacity of jute industry.

- In West Bengal strong labour unions frequently lead to problem of strikes, lockout and other labour problems, this has further decreased the competitiveness.

Measures taken for the jute industry

- Diversification of jute products such as clothing items, decorative items, matting of carpet improve durability, packing items, etc. has been done to increase the horizon of Jute Industry.

- Improve quality: Innovative ways of bleaching, dyeing, and finished goods processes the jute industry now provides finished jute products that are softer and have to luster with aesthetic appeal. Today Jute has been defined as eco-friendly natural fiber with utmost versatility ranging from low-value geo-textiles to high-value carpets, decorative, apparel, composites, upholstery furnishings, etc.

- Reduce cost: Efforts in R&D to strengthen the jute industry and implement newer technologies, diversified products, and improved machinery through intensive modernization. These will fetch more profit by reducing cost and has less market competition (synthetic counterpart) due to its eco-friendly property which has good prospects in the coming days.

- Jute cultivation is being expanded. There has been some dispersion, due to increasing demand from the sugar industry in UP and cement industry MP.

- Jute is environment friendly and renewable; hence its use must be encouraged e.g. by making it mandatory to use jute for packaging.

- Govt has issued orders like cement, sugar, fertilizer, have to strictly make use of jute production to packing the materials, Food Corporation of India, oilseeds, and tea sector also have to implement this order.

- National jute Manufactures Corporation has been formed to boost the jute industry.

Future prospects of the Jute industry

- The future prospects of the Jute industry, however, is bright due to the following:

- Diversification of jute products

- Environmental awareness

- Ban on polythene and plastic bags

- Increasing use for oil conservation

- Construction of bunds, river embankments, landslide protection

- Along with cotton, jute is also being used for apparel manufacturing.

any amount of gratitude to your platform would be less… All the parameters like content, presentation and to the point portion requirements needs a salute.!

Thanks

mandatory percentage of packaging of sugar (50%) and food grains (60%) in jute bags(data given in your article but the videoframe of THE HINDU provided by you provides different data)

REFER TH VIDEO IN TERMS OF PERCENTAGE , RECENT NEWS 100 20

Wonderful

Thanks for this presentation as it helped me alot in my project